Super-tweeter 1 as I found it. FS = 2700Hz, Re = 4Ohm.

Super-tweeter 2 in good state. FS = 2400Hz, Re = 4,6Ohm

Super-tweeter with a bad welding on the voice-coil. (Use frequency from 8KHz to 20KHz)

This wrong welding made by a previous protagonist was source of several issues:

DC resistance shifted down from the original (several turns of wire being welded together), deformed voice-coil, lost of efficiency because of a bad positioning of the powered section of the voice-coil into the magnetic air gap.

It was needed to write technical specifications for the manufacturing of a new custom made voice-coil as close as possible to the original, to strip down the existing voice-coil without making any damage to the beryllium while preserving the spider as much as possible, to put back a new voice-coil.

In the end I had to make a new spider but the beryllium diaphragm remained 100% intact. The assembling of the new voice-coil, the new spider and the diaphragm went perfectly and the measurements shows excellent results when comparing the repaired tweeter with the original.

Comparison of the 2 super-tweeters.

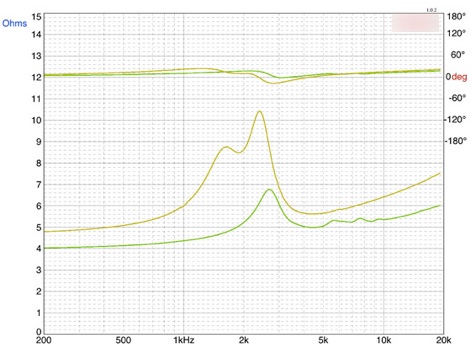

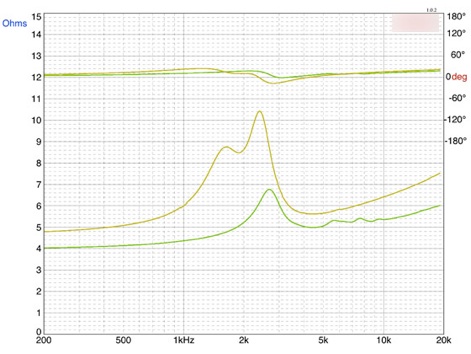

At the left, comparison of the two super-tweeters:

The green curve shows the super-tweeter with the bad welding.

The yellow curve shows the super-tweeter in its original condition.

One can easily see the shifted DC resistance.

I can’t explain the bump at 1600Hz on the original super-tweeter though, any idea? In any case, it has no impact on sound.

I think I can explain the small bumps between 5 and 10KHz on the damaged super-tweeter: vibration of some damaged and jutted-out turns of the voice-coil.

A new voice-coil is needed for the super-tweeter 1 and to consider for the super-tweeter 2.

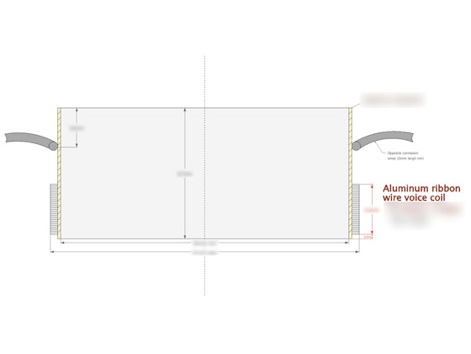

Technical specifications for the new voice-coil after a careful analysis of the one from the super-tweeter in good condition.

New high-end voice-coil. 4 different models were ordered to get as close as possible to the original.

Disassembly of the voice-coil and spider. I did not succeed on the protection of the original spider, a new one is needed !

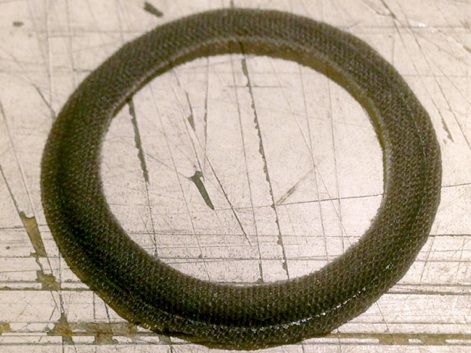

Fabrication of a new spider (with a custom made mold).

New spider.

Old spider.

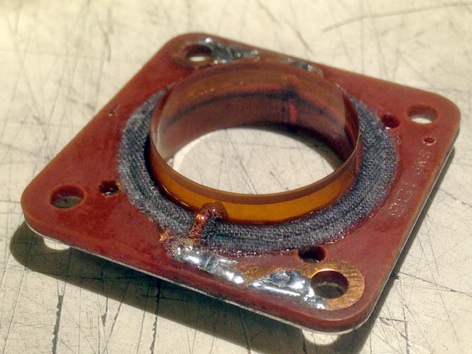

Set before assembling. Note the perfect state of the beryllium diaphragm.

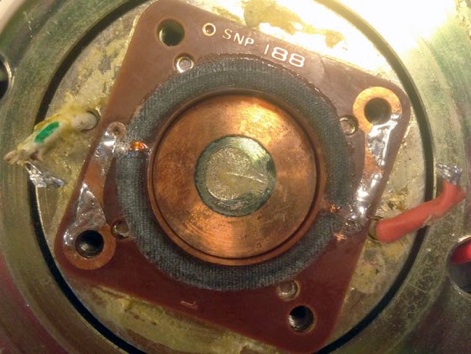

After assembling.

After assembling.

Good centering.

Projects ≫ Project S-F1 custom ≫ Super-tweeter repair

Pioneer S-F1

Super-tweeter repair

Reassembled super-tweeter.

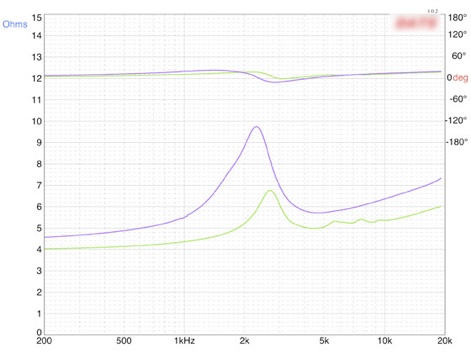

Comparison of before repair (in green) and after repair (in purple).

FSbefore = 2700Hz, FSafter = 2300Hz

Rebefore = 4Ohm, Reafter = 4,4Ohm

Lebefore = 0,060mH, Leafter = 0,075mH

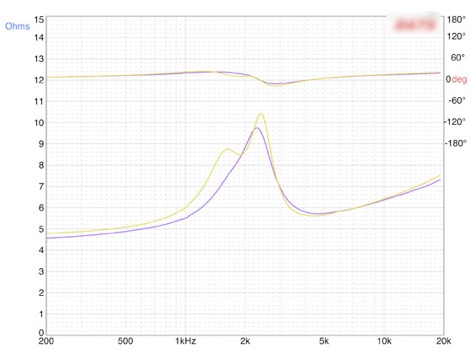

Repaired super-tweeter VS super-tweeter in good condition.

FSrepaired = 2300Hz, FSoriginal = 2400Hz that being 4% of difference

Rerepaired = 4,4Ohm, Reoriginal = 4,6Ohm that being 4% of difference

Note the very good similarity after 5KHz

Super-tweeter with bad welding VS super-tweeter in good condition.

FSwelded = 2700Hz, FSoriginal = 2400Hz that being 21% of difference

Rewelded = 4Ohm, Reoriginal = 4,6Ohm that being 13% of difference

Lewelded = 0,060mH, Leoriginal = 0,072mH that being 17% of difference