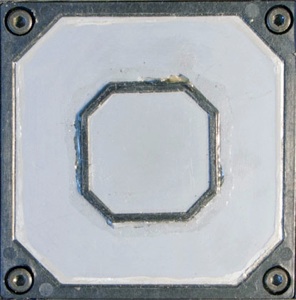

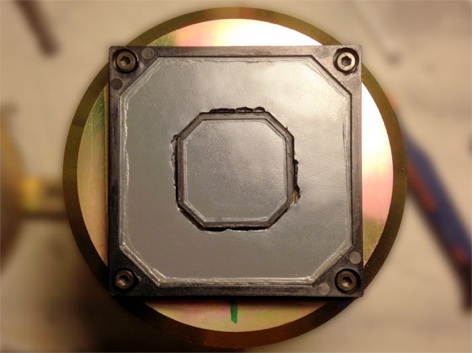

Tweeters with damaged beryllium diaphragms.

(Use frequency from 2,5KHz to 8KHz)

Dismantling with force of the tweeters by a previous protagonist led to some small cracks on the inner side of the beryllium diaphragm. The inner surround was not meticulously cut before to pull on the tweeter. It ripped while holding a few parts of beryllium leading up to a disaster.

Some kind of glue were then applied at the reassembling hopping that it would behave as a surround. Even though it was functional, this repair seemed inappropriate to me and I decided to redo it properly.

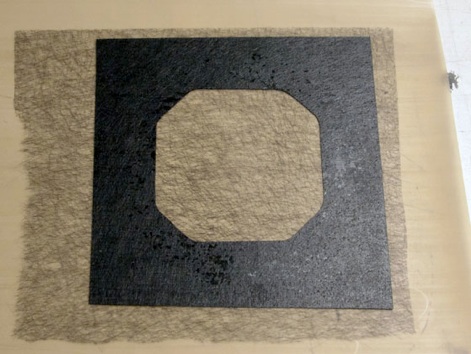

After days of researches, I finally made some ultra light and stiff carbon frames to reenforce the inner perimeter of the diaphragms. Then I made an home made butyl rubber surround.

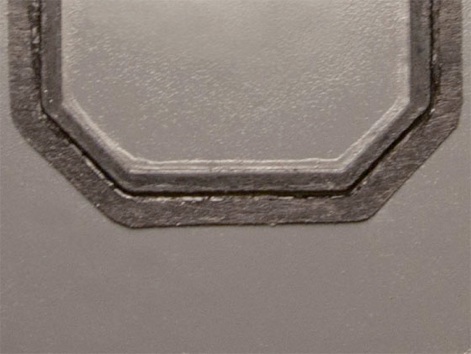

Tweeter after cleaning of the diaphragme. One can see the missing parts of beryllium.

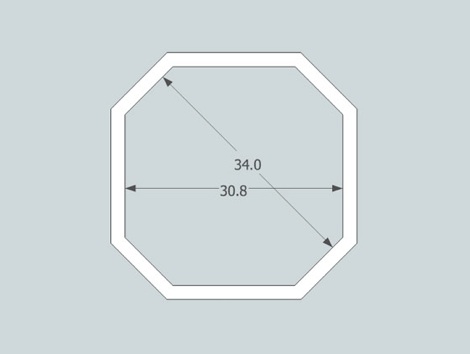

Technical specifications for the new carbon surrounds holders. They are less than 2mm wide and thin as a sheet of paper.

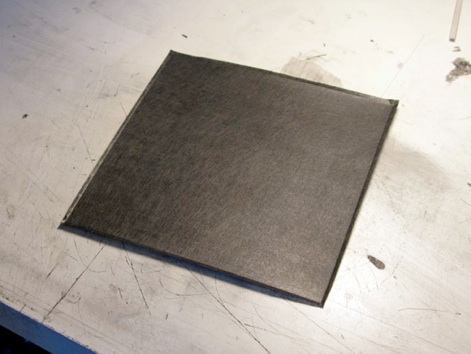

Many trial with different carbons and resins allowed me to find satisfaction in the relation between weight and stiffness, with a density of 75g/m2 !

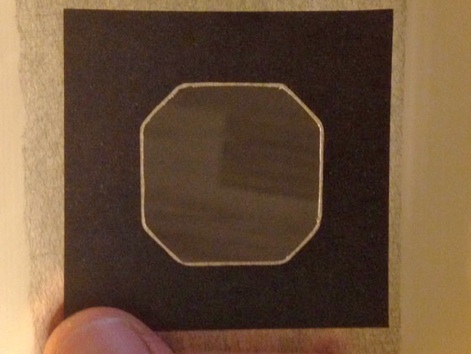

Quick trial to validate the feasibility of cutting and positioning of the carbon frames before to make final parts.

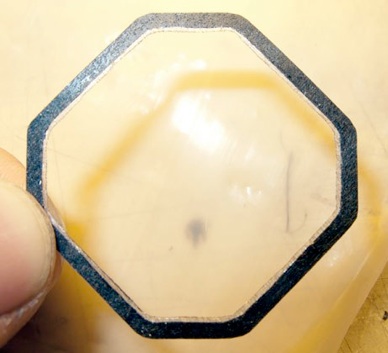

Work in process on a final part. The «soft» carbon with hold some butyl rubber.

Coating of the inside with liquid butyl rubber.

result after cutting of the inside.

Result after cutting of the outside.

0,044 grams !

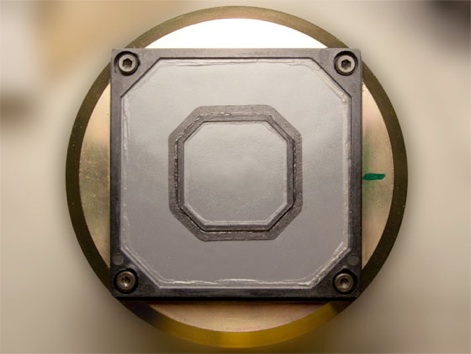

After mounting on the diaphragm.

Close-up on the micro surround.

Work done.

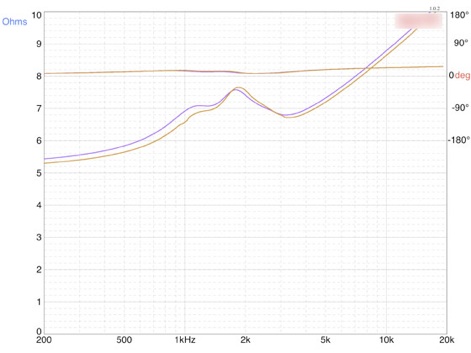

Tweeter 1 before/after restoration. 2 identical curves.

Pioneer S-F1

Tweeters repair

Projects ≫ Project S-F1 custom ≫ Tweeters repair

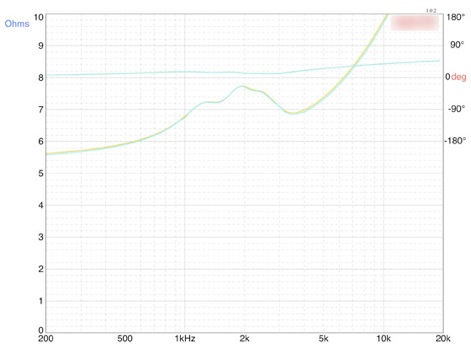

Tweeter 2 before/after restoration. Almost no difference.