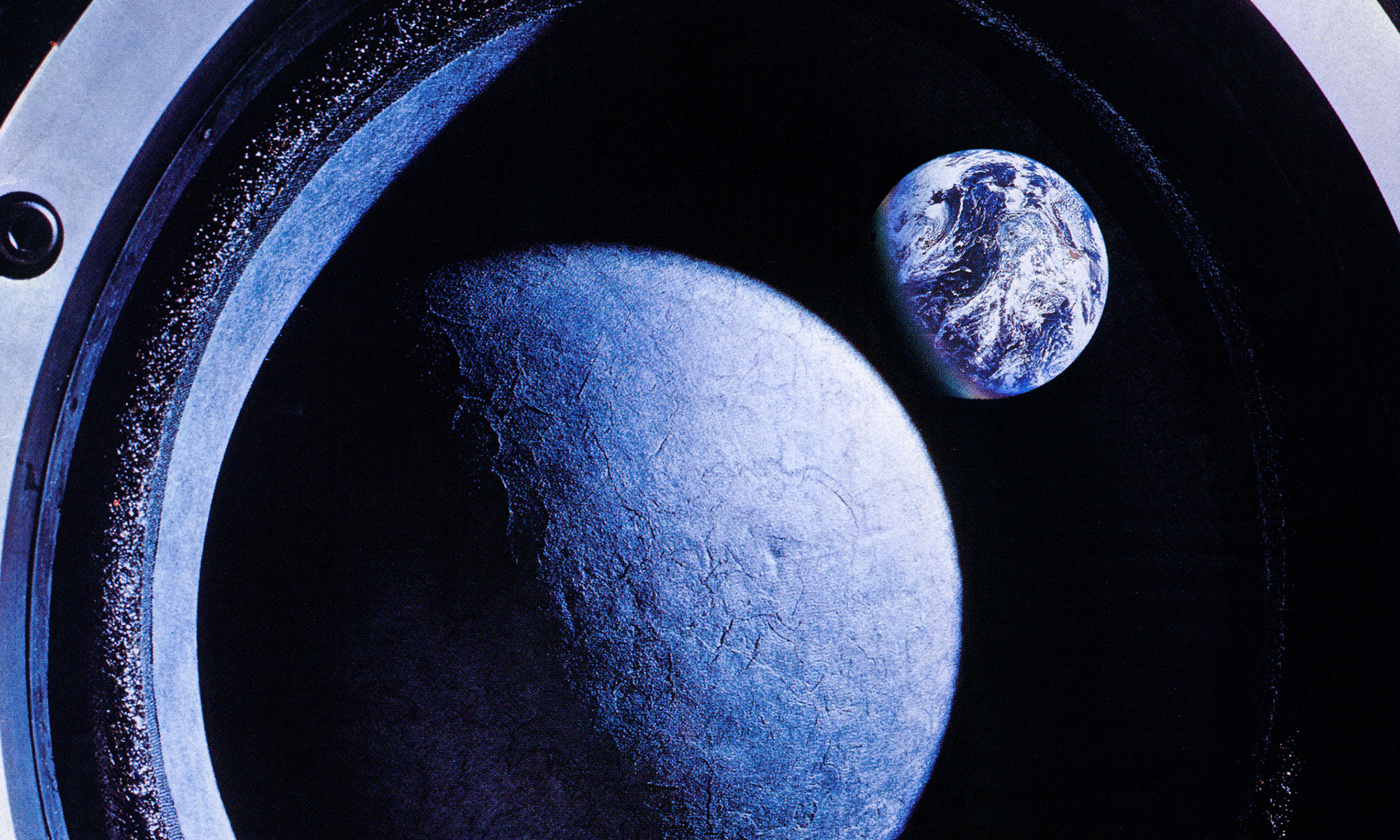

Extraordinary sound reproduction by modifying Sony APM-33W.

In overall surpassing the sound of stock APM-4 !

This is the story on how I revealed the huge potential of these speakers.

- New treated synthetic leather surrounds: available on order for the Sony APM-4, APM-77W, APM-66ES, APM-55W, APM-33W, APM-700, SS-X300. Please contact me.

- New crossover filters started from scratch: Development boards all adjusted to the final parameters are available. Commercial boards soon available. Please contact me.

- Bass reflex port modified

- Replacement of speaker terminals and use of Teflon insulated OFC copper cables.

- New stands that places the speakers at an optimal height for our European sofas.

Starting point for this project, I wanted to develop surrounds cheaper to produce and easier to mount than my previous impregnated fabric ones, while keeping some of the advantages of fabric such as damping and durability.

After long researches I finally found the right material through a very high-end synthetic leather.

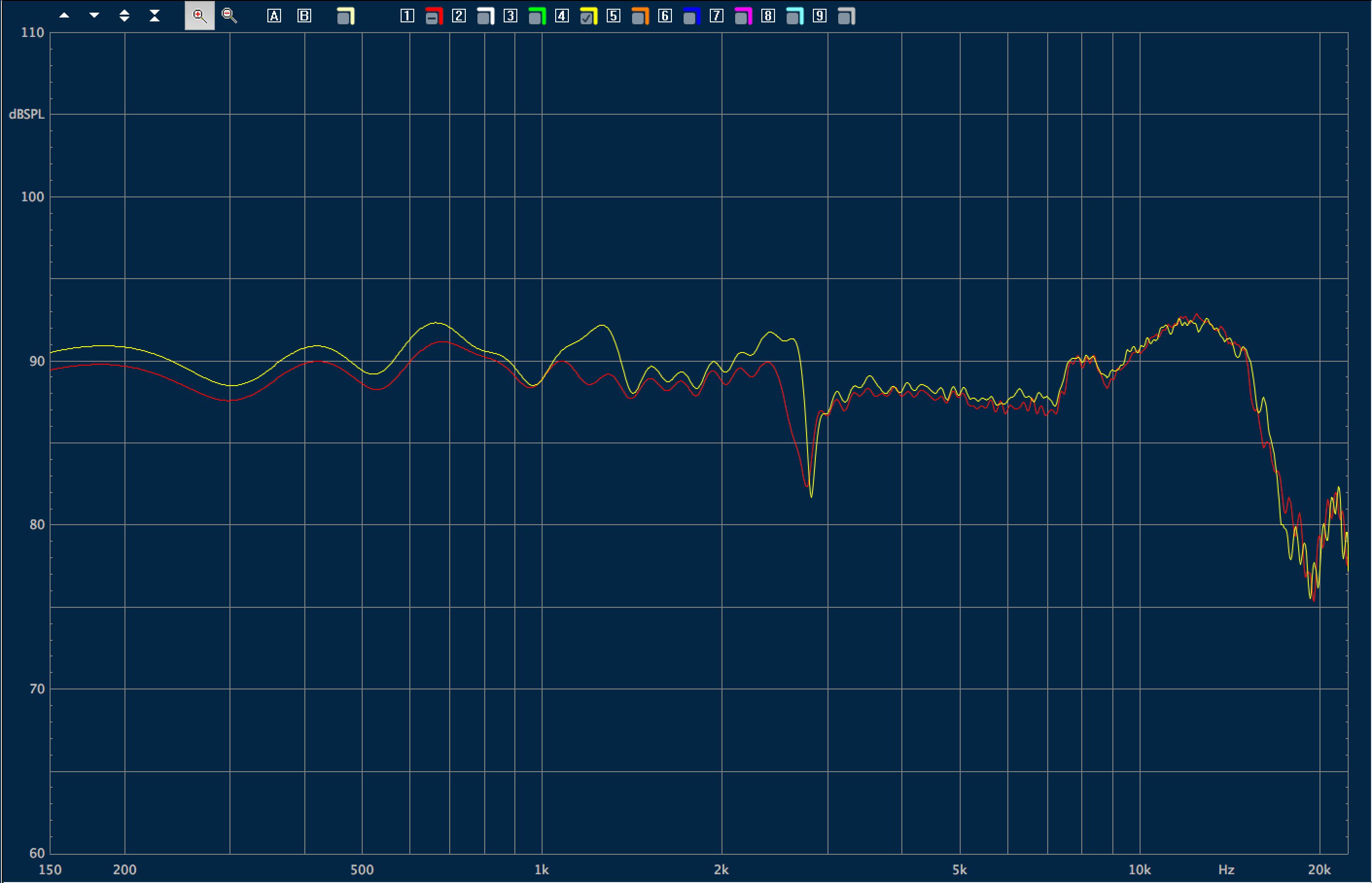

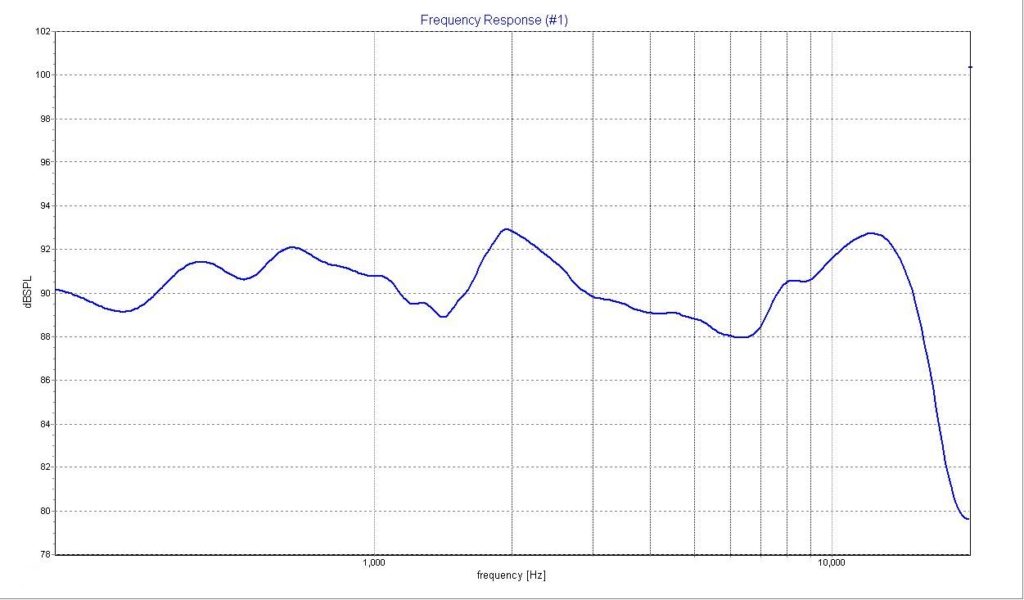

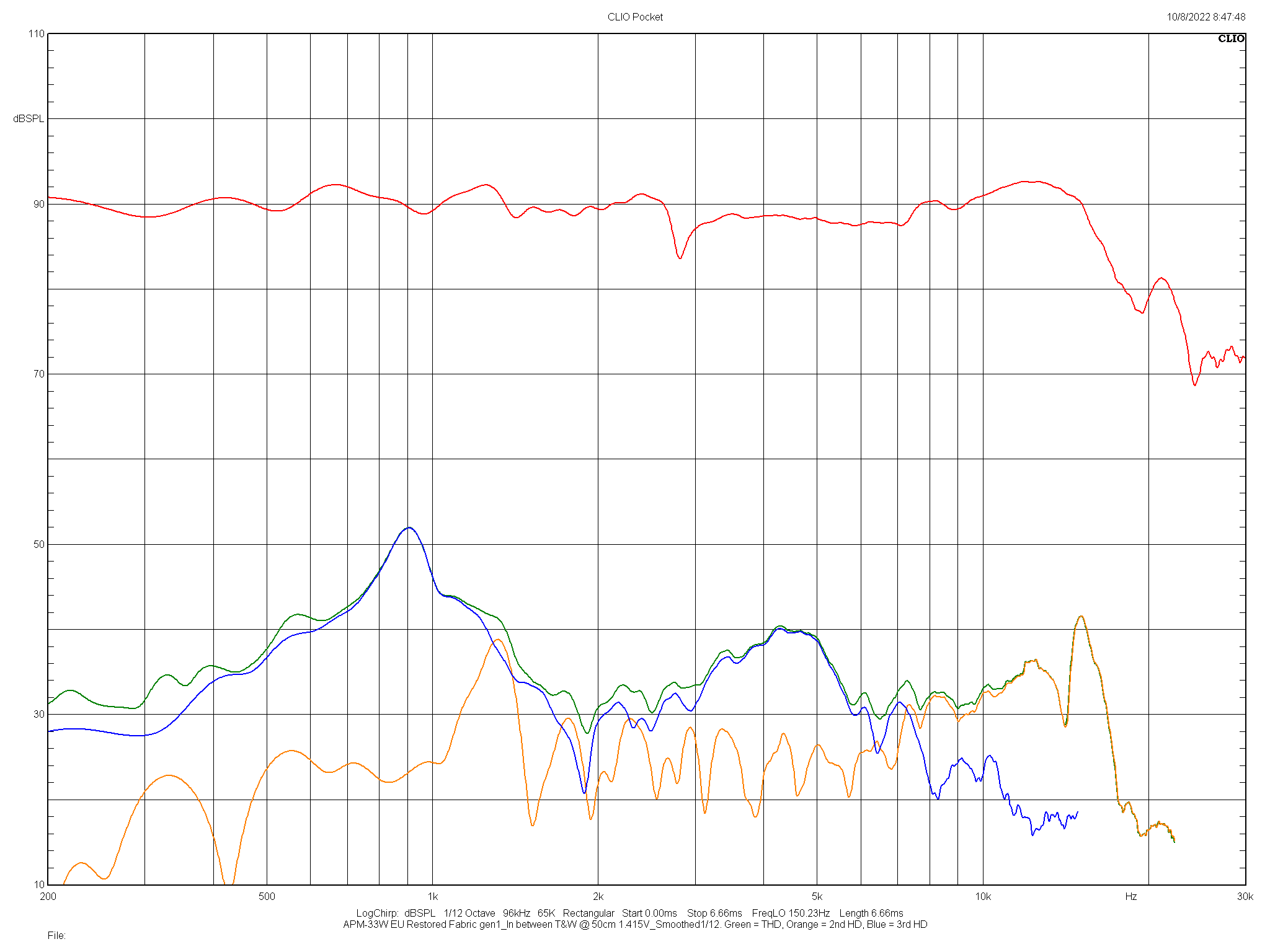

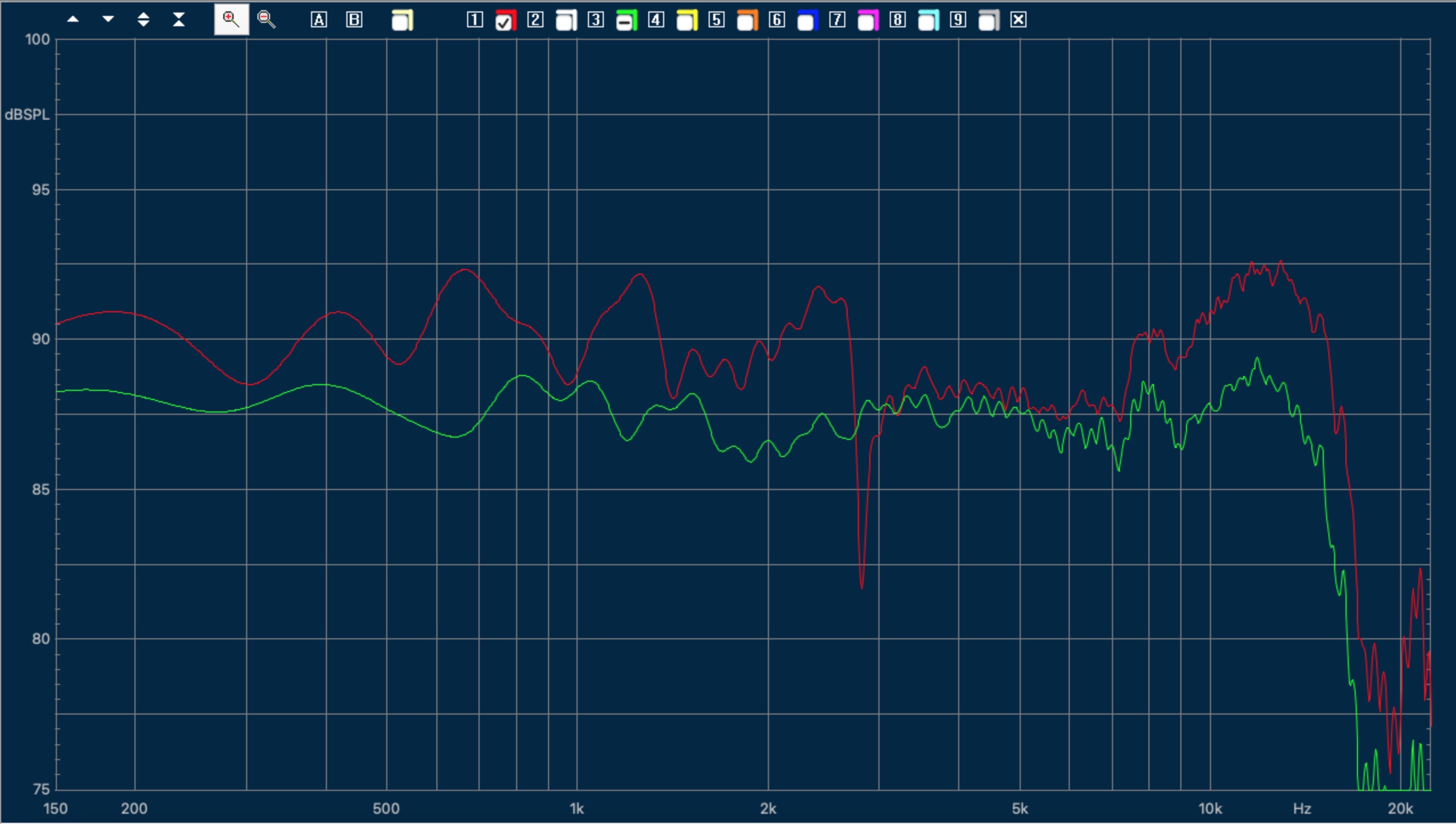

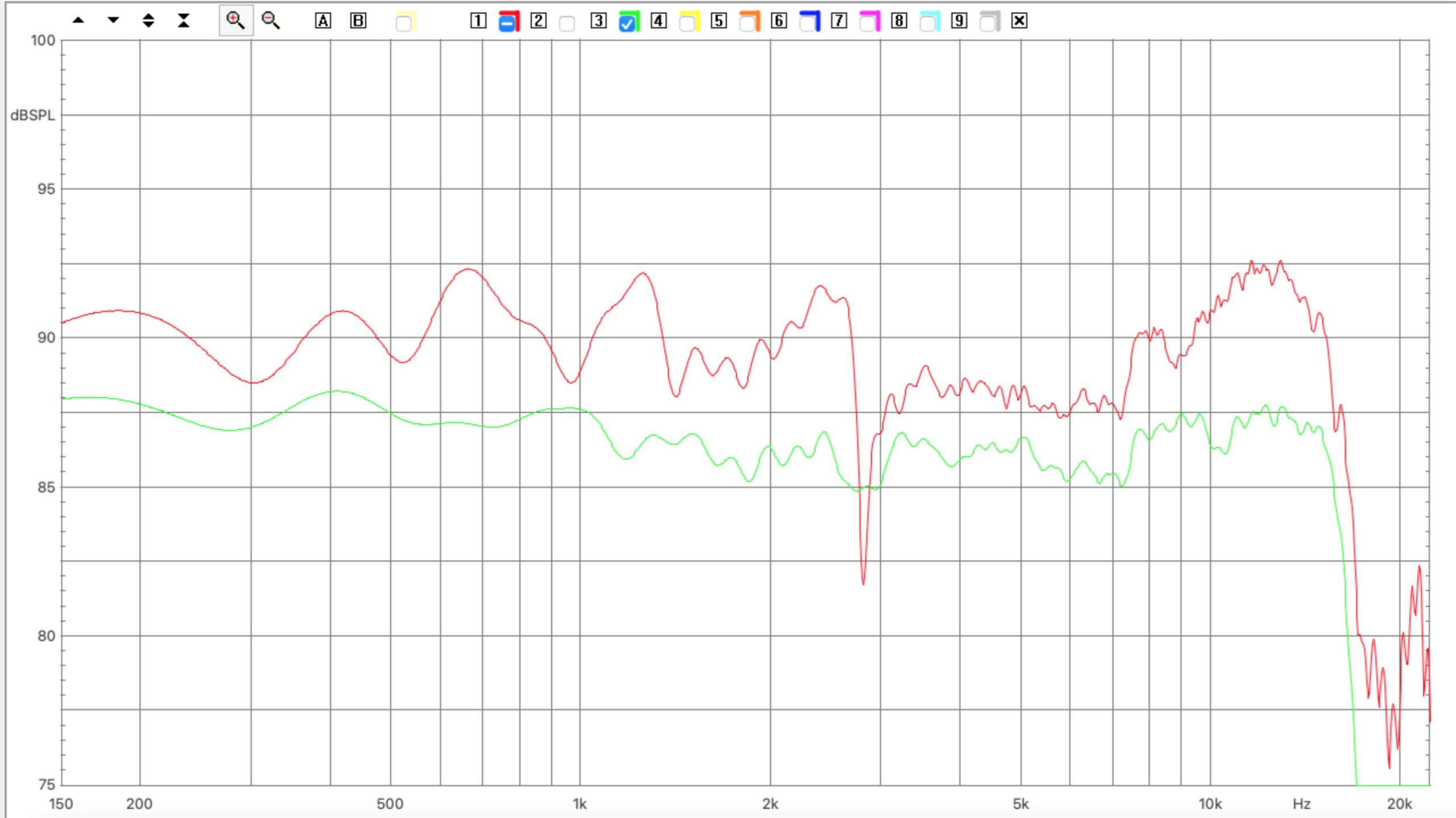

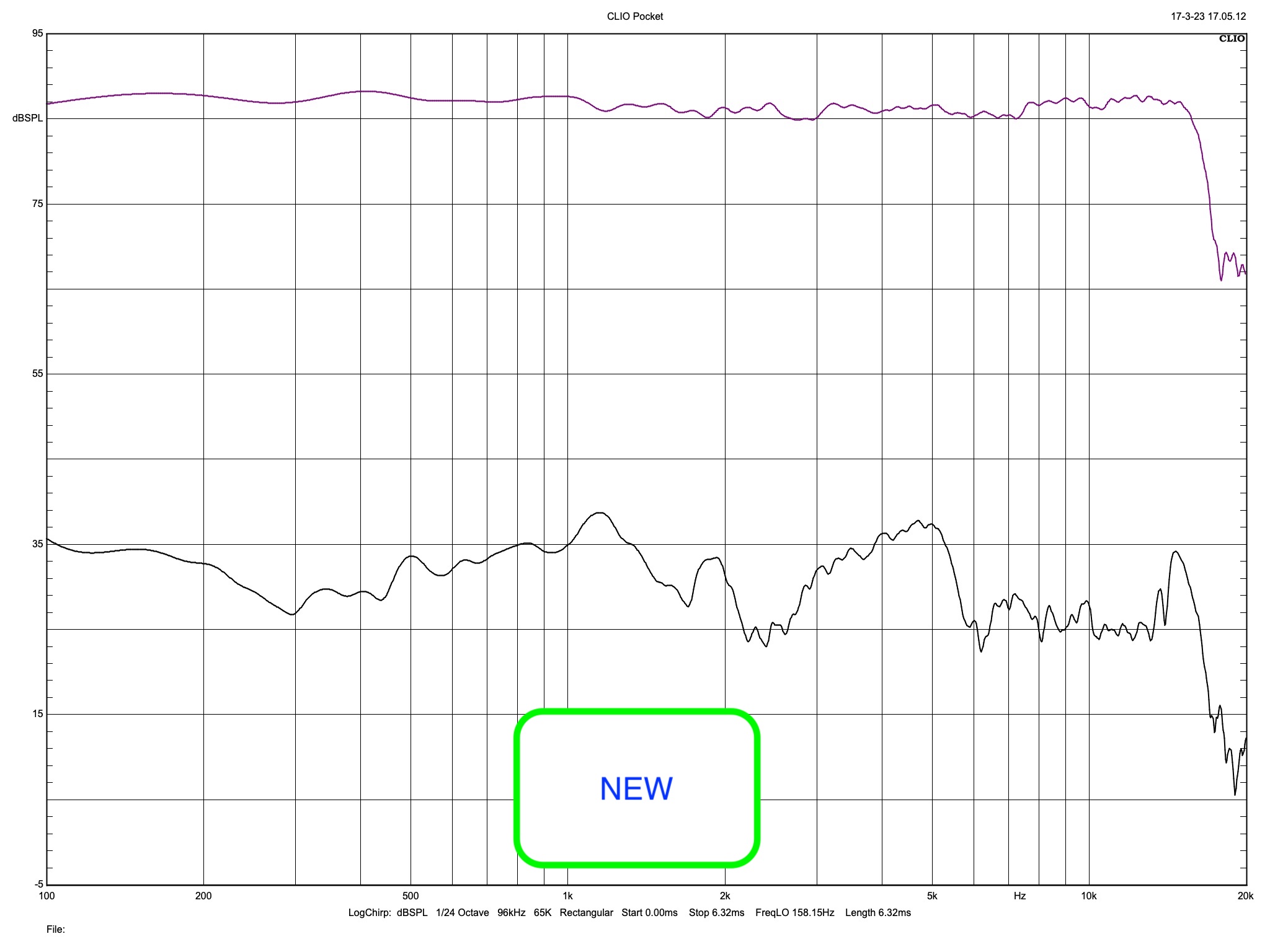

All that remained was to test it in real conditions on my APM-33W Export version, which had come out of their storage boxes for the occasion. With the acoustic measurement, I quickly noticed an improvement compared to the treated fabric surrounds with better damping around 1KHz and 2.5KHz :

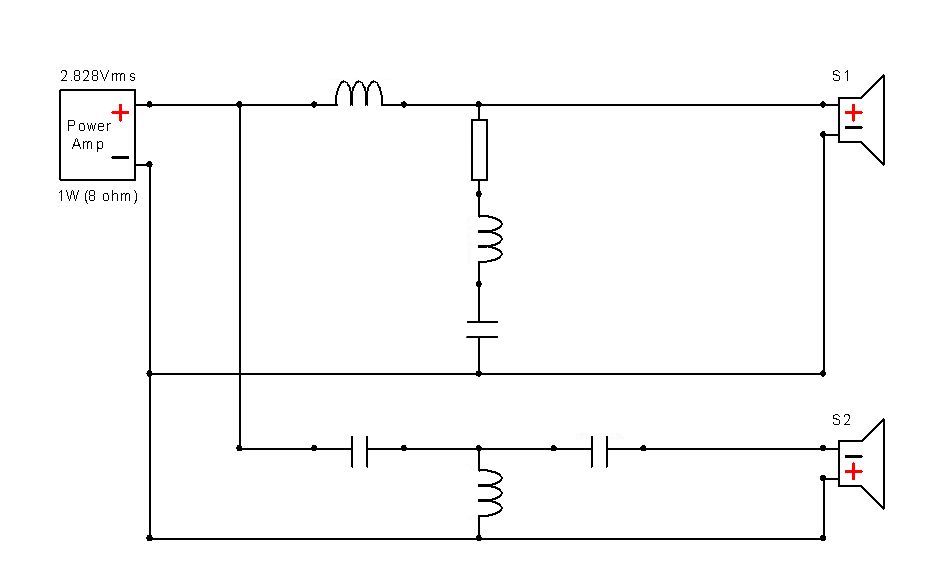

However, I remembered a better restitution from the Japanese domestic version of the APM-33W, and decided to carry out an analysis to understand what was happening. In fact the Japanese and Export APM-33W don’t have the same crossover filters and my conclusion is that while the Japanese APM-33Ws were probably developed for HiFi use, the Export APM-33Ws were rather developed for the flattering listening of electronic music.

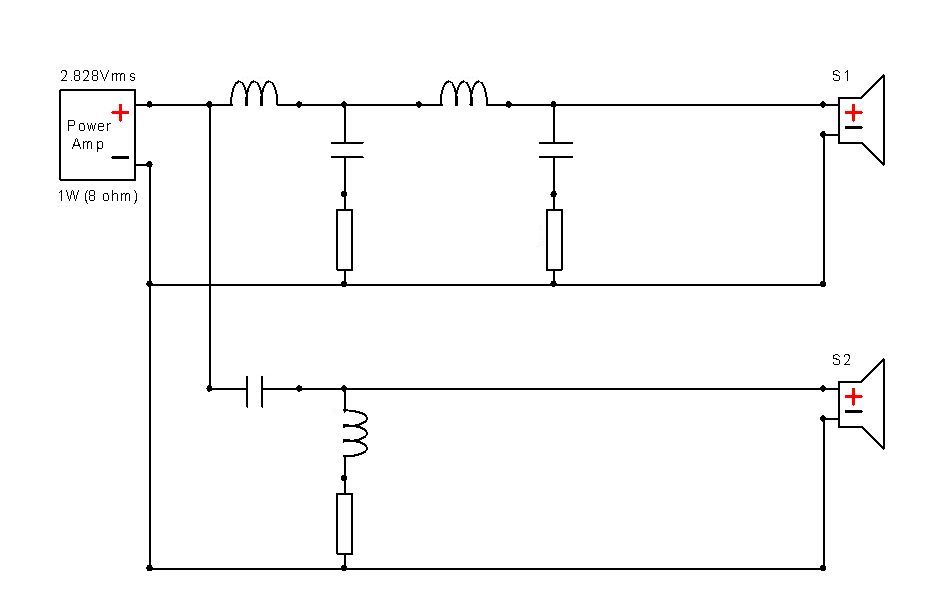

- Japanese version: woofer filtered by a 6dB per octave followed by a notch at 2.6KHz, tweeter filtered by a 18dB per octave. Crossover at 2.5KHz, response within +/-3dB.

- Export version: woofer filtered by a 24dB per octave, tweeter filtered by a 12dB per octave. Crossover at 2.6KHz, response within +/-3dB.

If the Japanese version is slightly better than the Export version, both of them were developed for mass market and with compromises on the crossover frequencies. Nothing to be ashamed here as nowadays mass production speakers are most of the time worse in their compromises. Both versions use the trick of cutting the woofer exactly at the breakup of the diaphragm, without taking advantage of the ability of the tweeter to go below. Crossing with the tweeter at a lower frequency would have improve the ability of the speakers to play any records but would have cost much more in filter parts.

The Japanese version has the merit of dealing with the splitting of the woofer’s diaphragm around 2.6KHz by the use of a notch filter, while the export version does without a notch through a very steep cut which results here in an imperfect phasing at the crossover frequency.

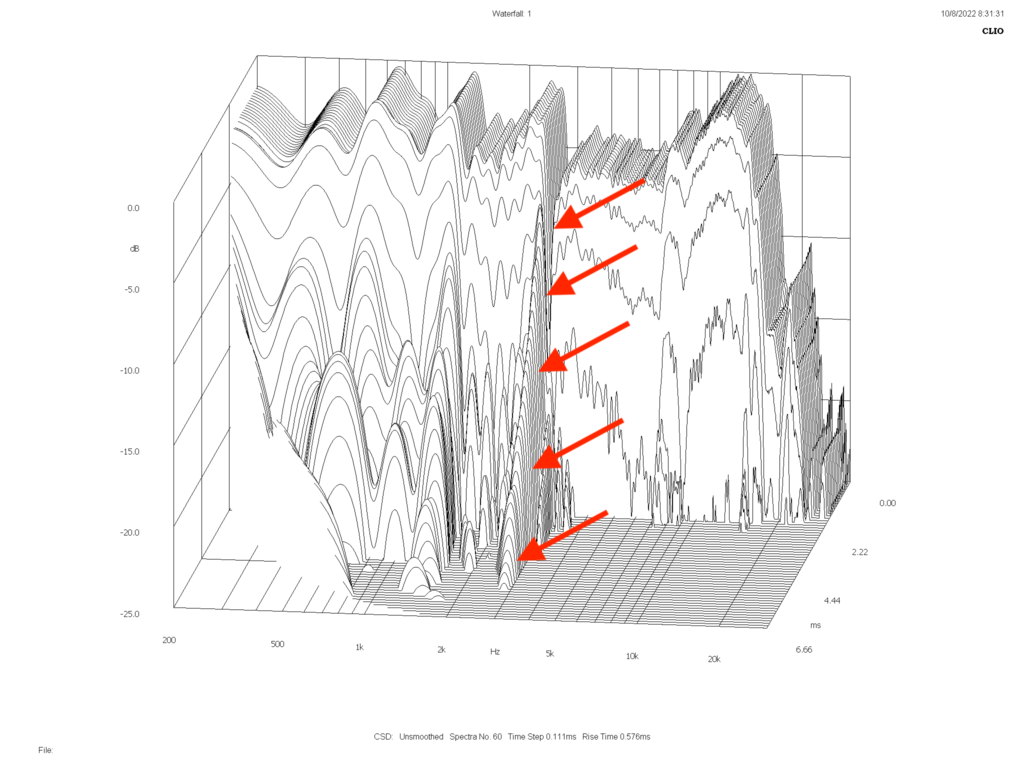

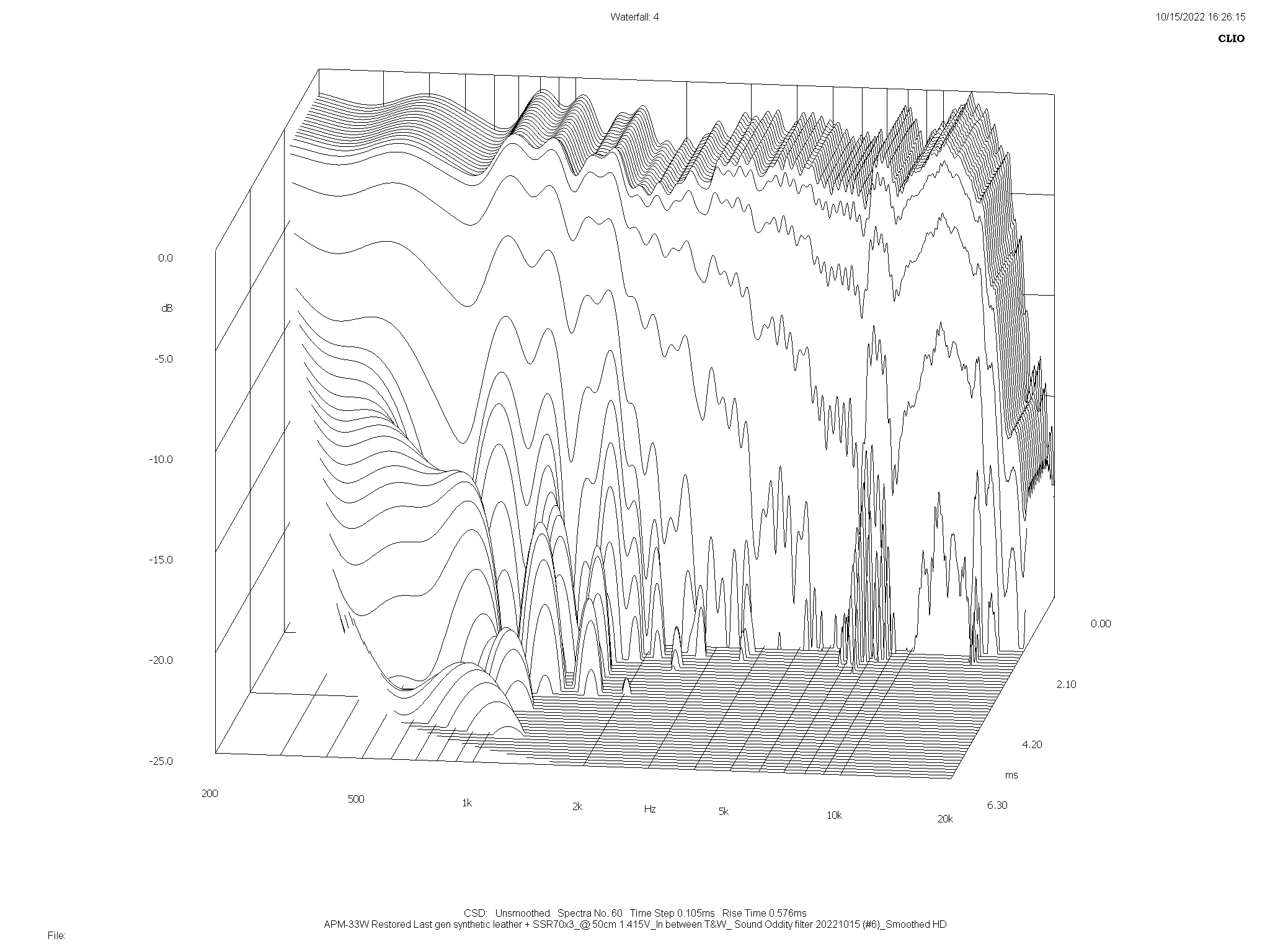

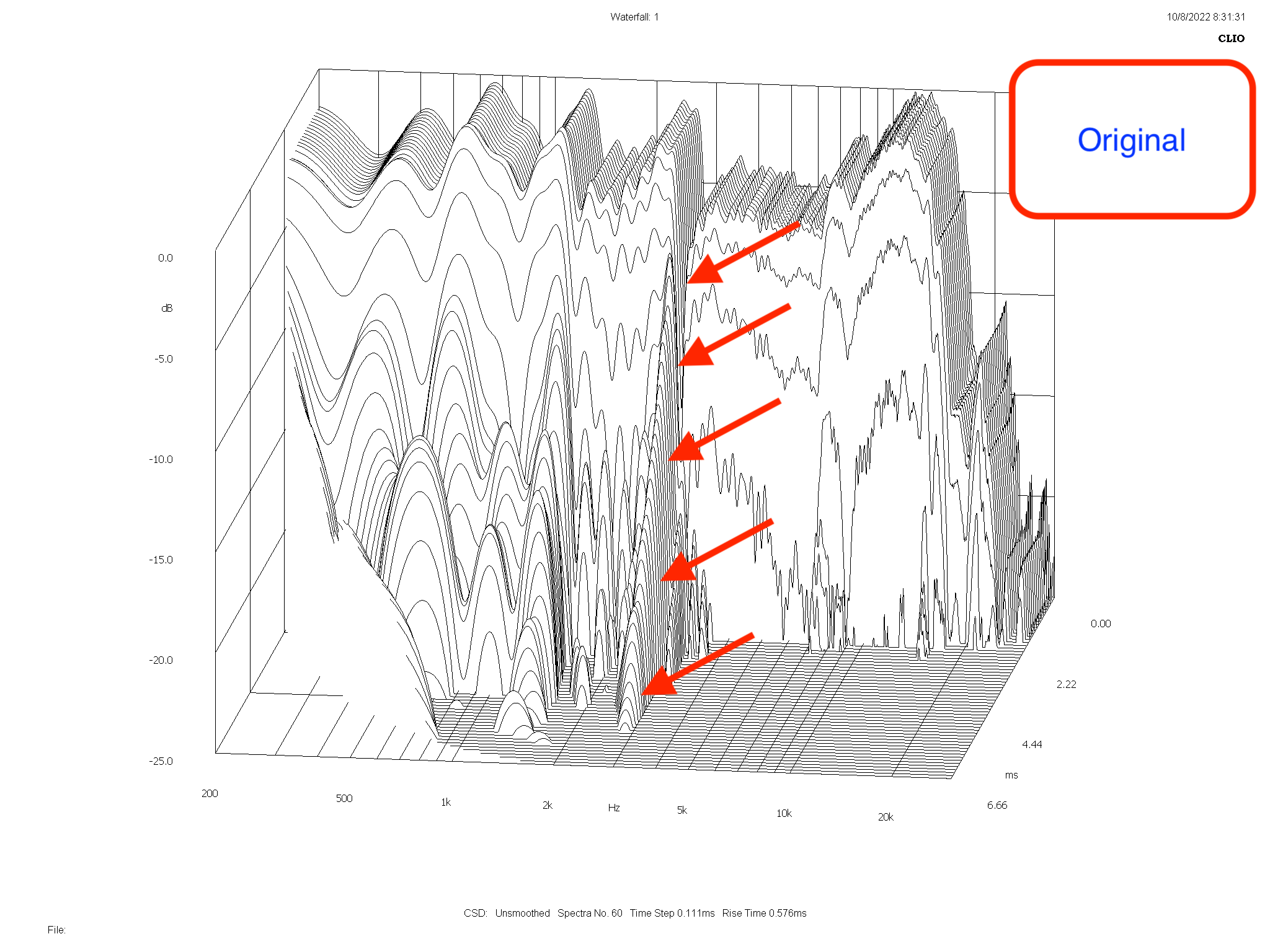

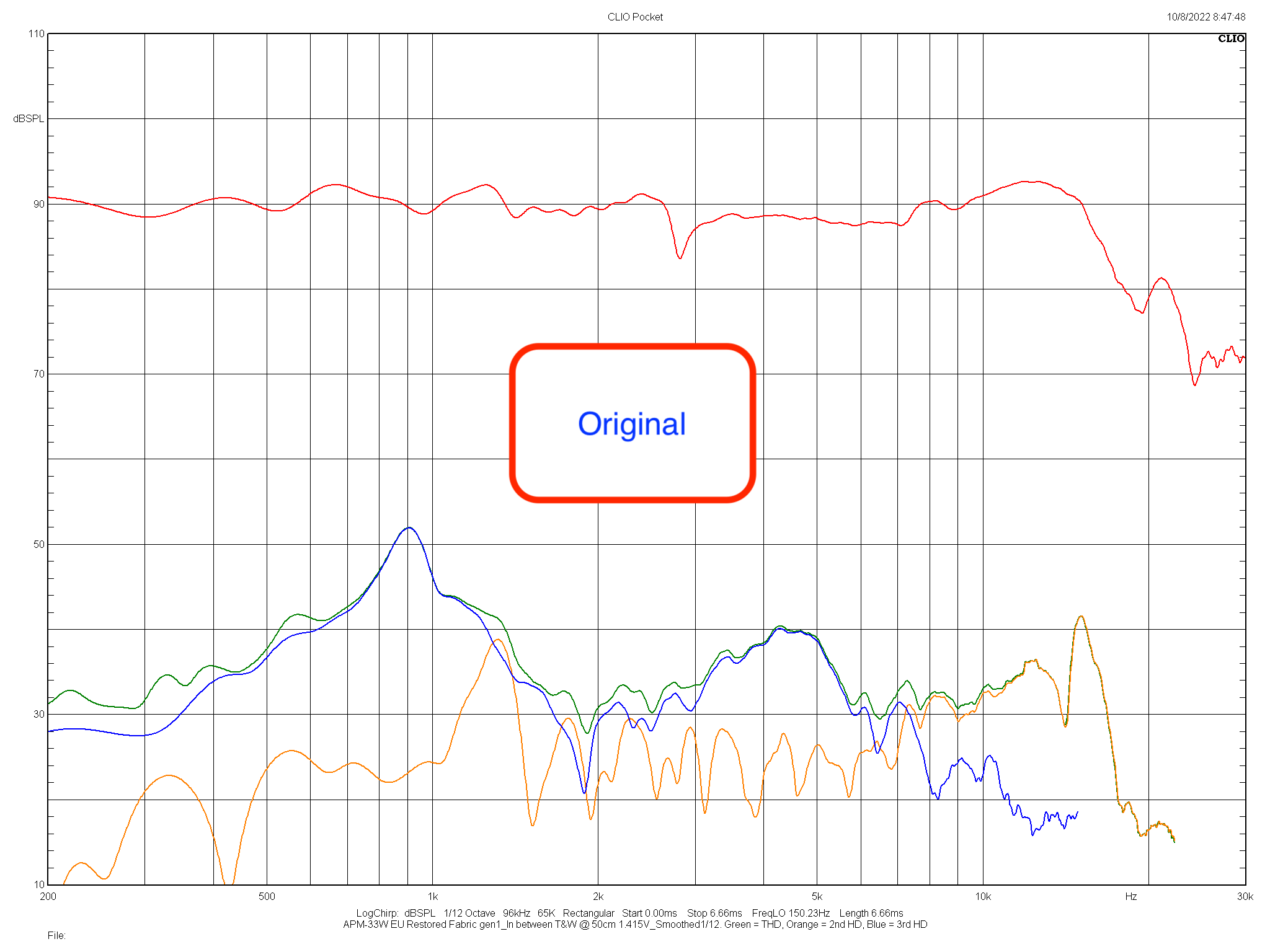

We can see on the waterfall of the export version that unfortunately, the breakup of the membrane is not processed which results in auditory fatigue during the reproduction of these frequencies. This splitting peak is also found on the distortion at around 900Hz which will have an impact on the clarity of the voices.

It was clear to me that a huge potential was sleeping here and I decided to develop a new filter with the specifications to stay within +/-1dB on the on-axis response curve, to correctly handle woofer splitting (rapid damping on the waterfall), to stay at a THD of less than 40dB from the on-axis response curve and to have the lowest possible crossover frequency with an impedance not going under 4ohm.

After many filter simulations and tests, I achieved a very impressive sound reproduction surpassing my estimations. An extraordinary definition, a very dynamic and realistic sound, a deep and precise 3D soundstage, a fast and clean bass response.

When simulating the bass reflex system, it turns out that the original tuning of the Export version deliberately puts the bass forward and depending on your room it can be heard on a few recordings. After increasing the length of the vent to have something more linear, everything went back to normal with an even more impressive quality as a result.

Here are the characteristics that I was able to obtain:

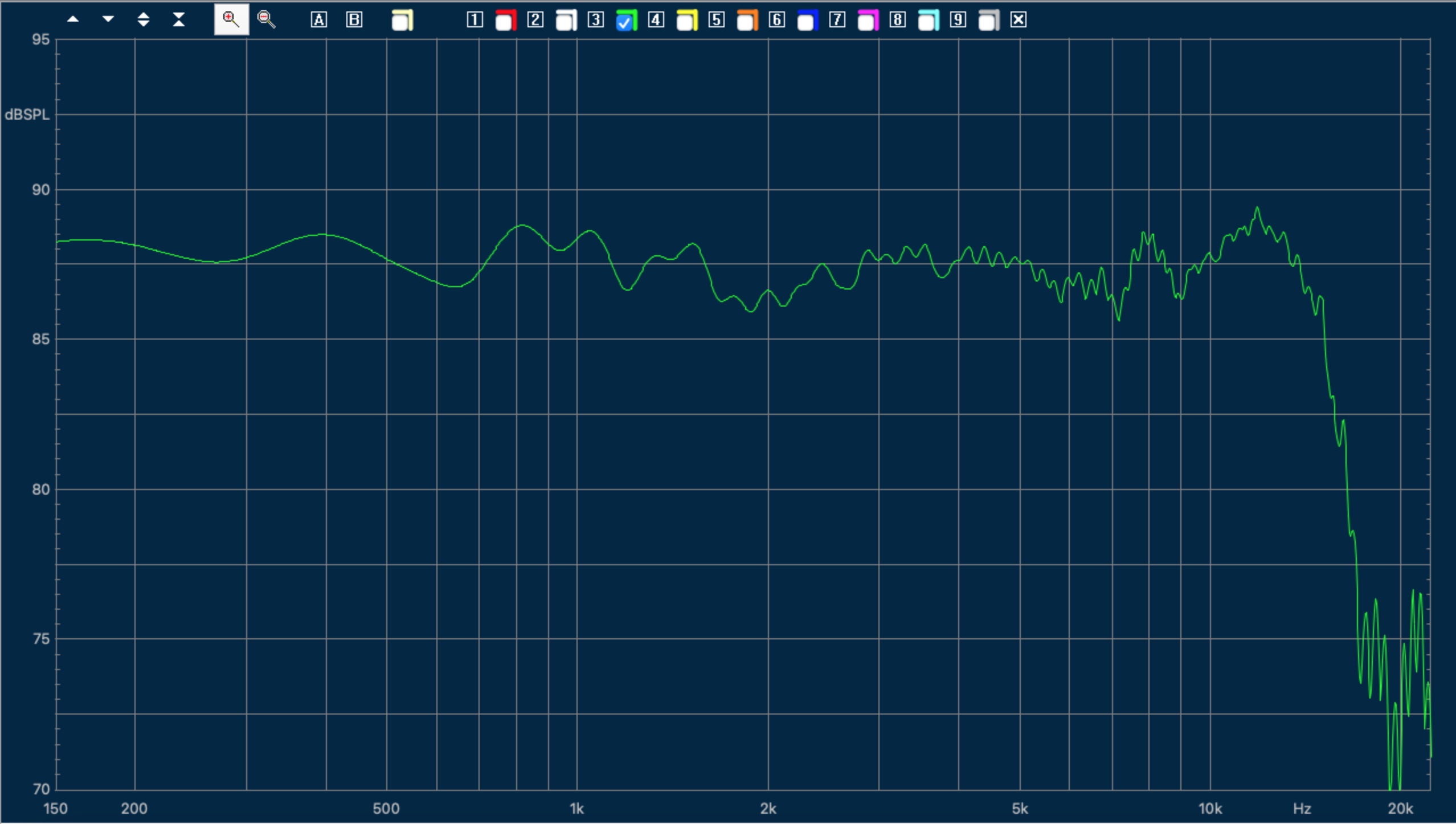

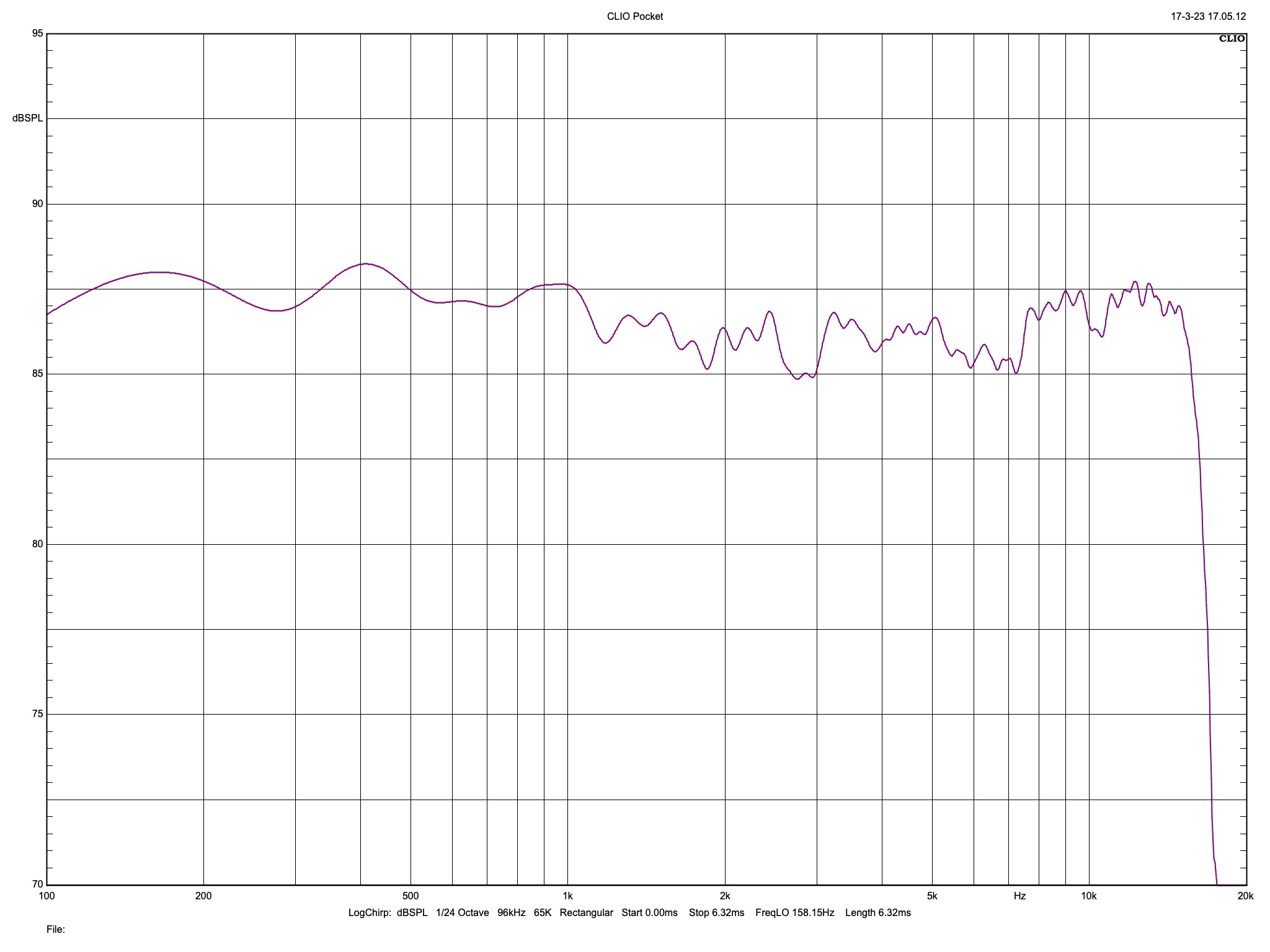

- On axis response curve within +/-1.3dB against +/-2.5dB original

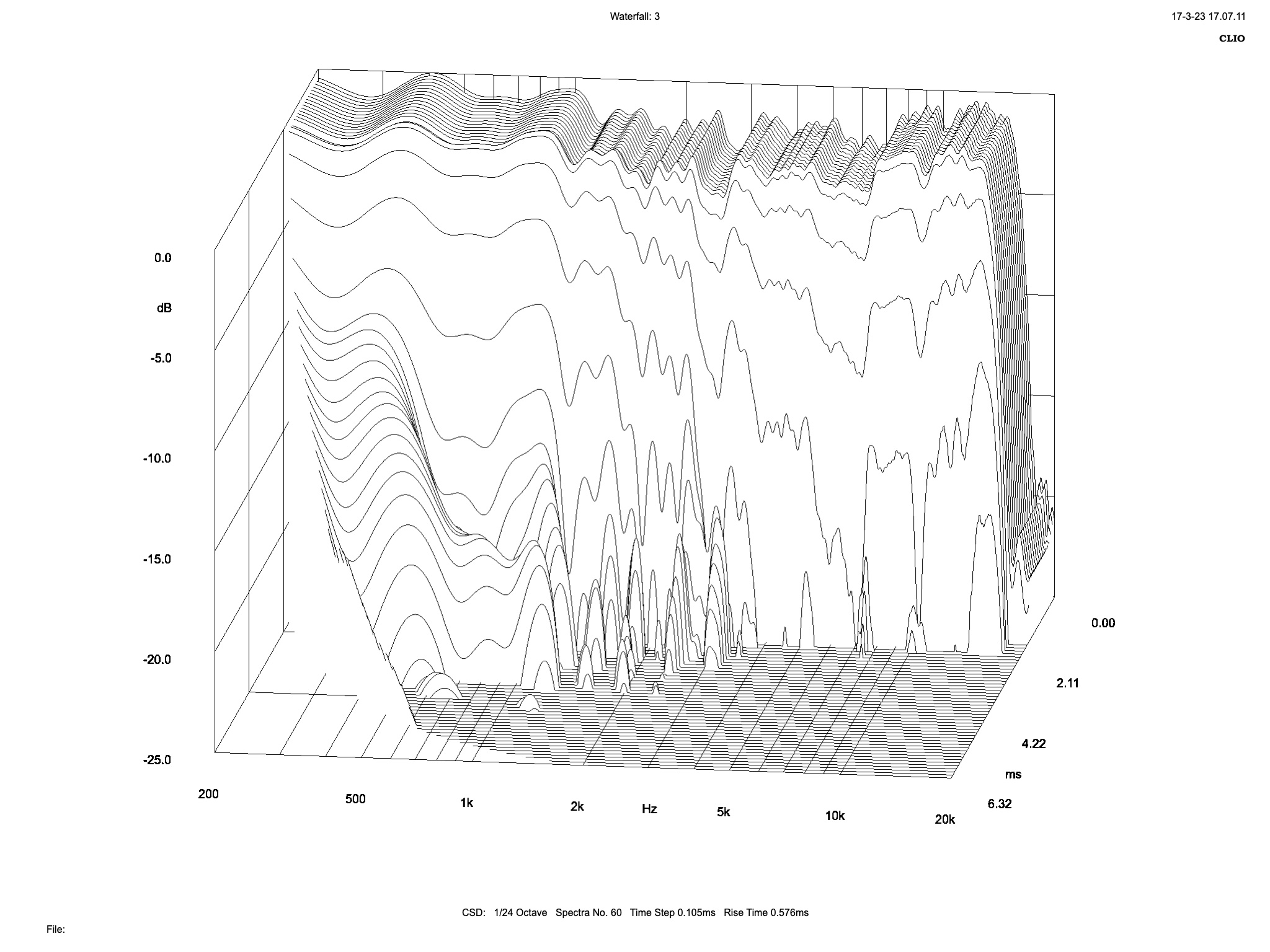

- No storage of energy on the entire response against resonance at around 2.6KHz original

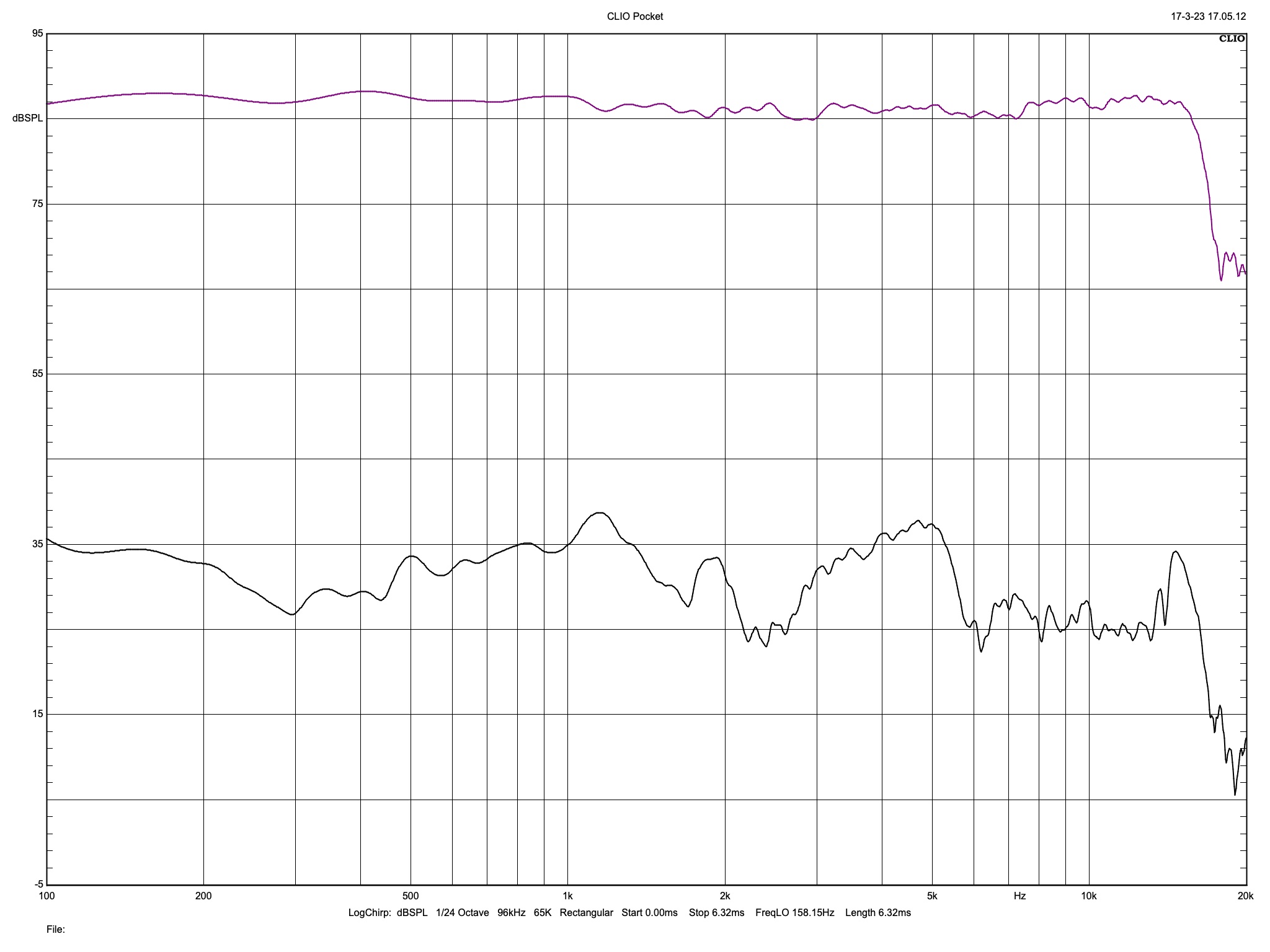

- Distortion at about 45dB under the on-axis response curve against about 35dB original

- Crossover frequency at around 1.8KHz against 2.6KHz original

- The response extends up to 16KHz at -3dB.

- Impedance at a minimum of 6ohm

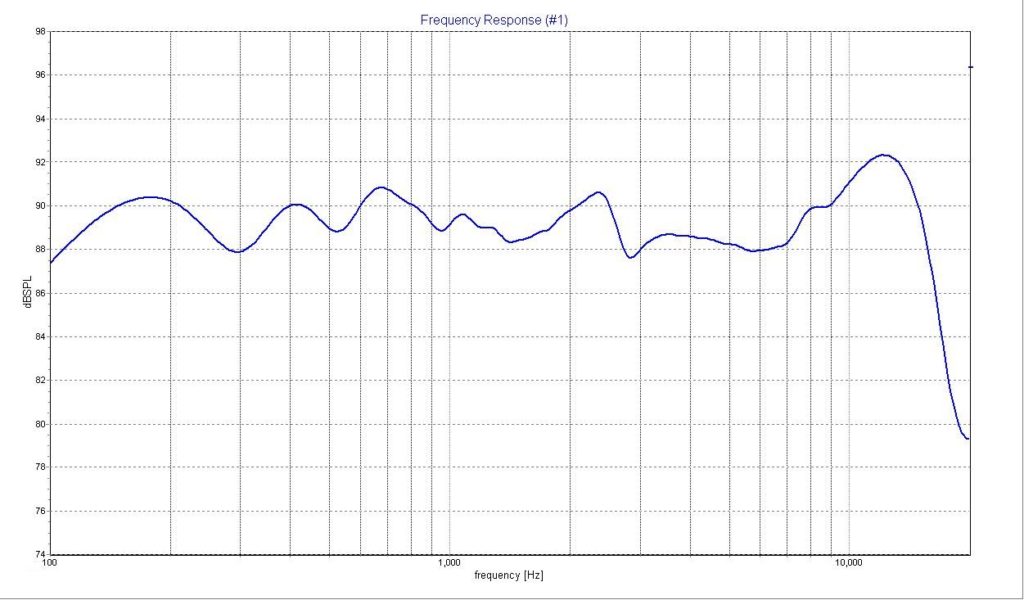

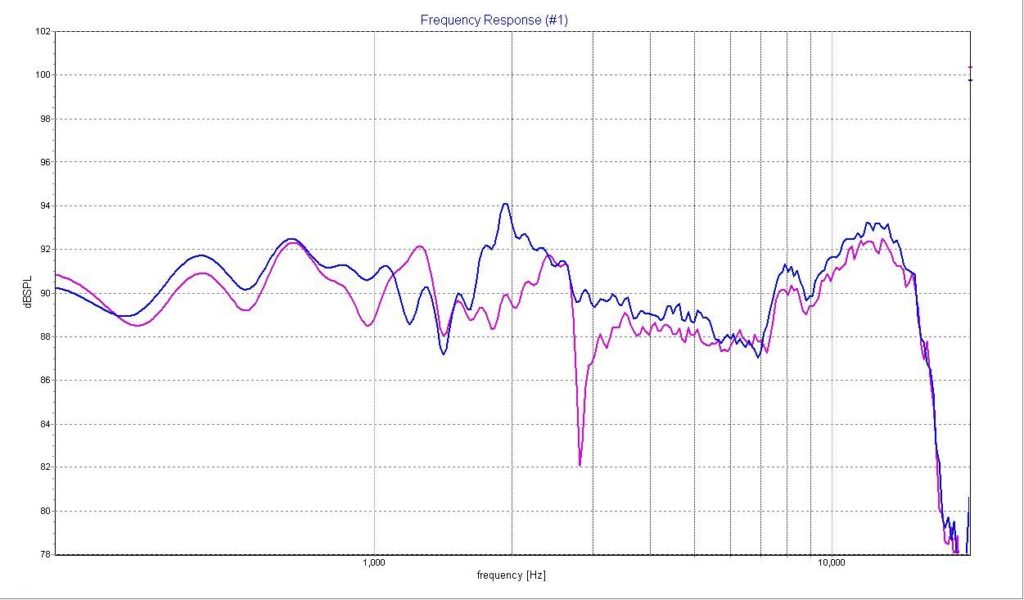

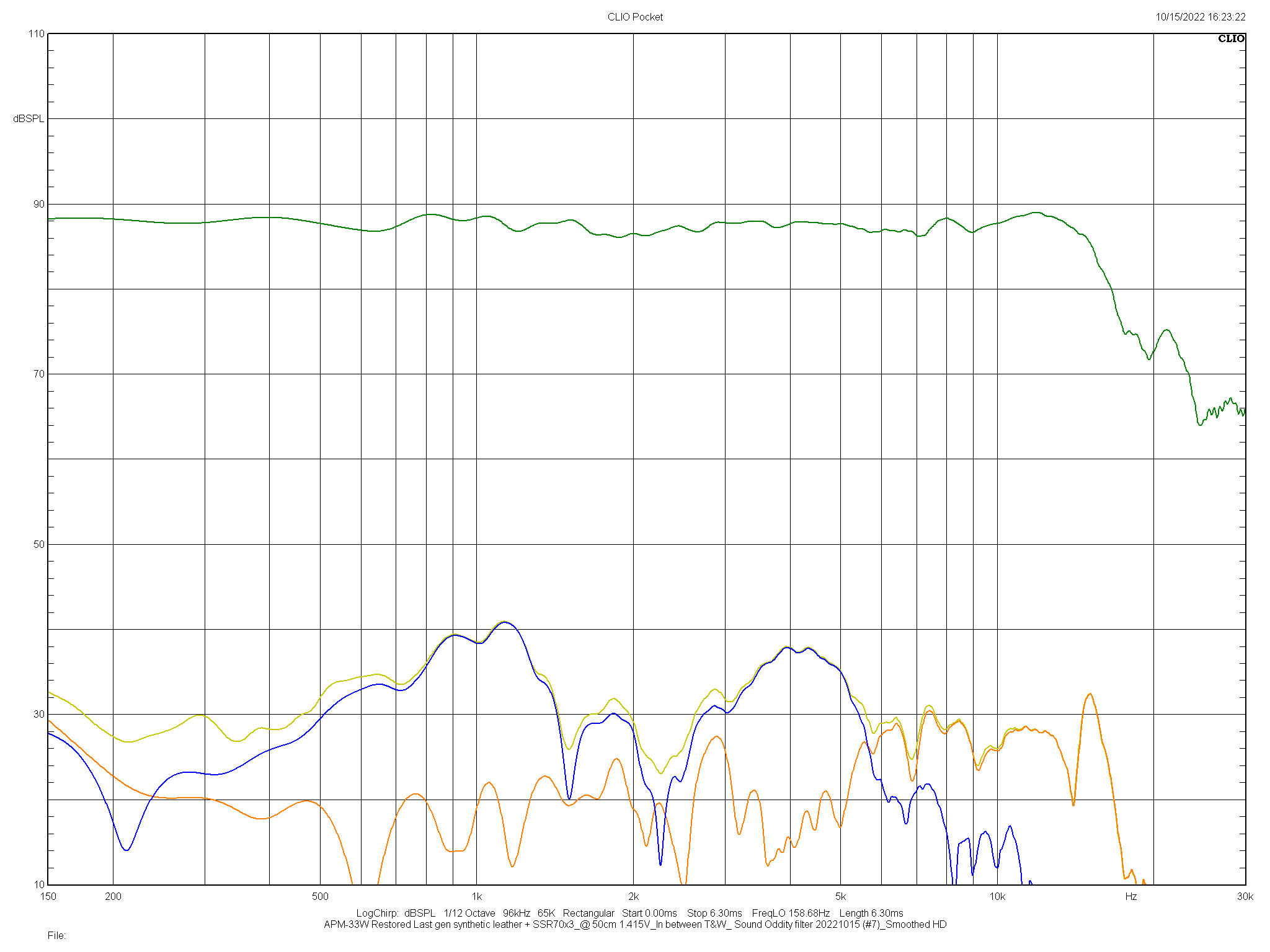

Here are some measurements. Please pay attention to the scale and the fact that no smoothing is applied. This is way more revealing than the current standards which uses 1/3dB/Octave smoothing and a 10dB scale.

One could question about the response only going up to 16KHz but I can reassure you that no customer test listener was able to distinguish that the highs were not going up to 20KHz. I believe this trade off to be a big win because it comes from the fact that the tweeter has a big surface area which allows it to go low with a realistic impact. The level of details is absolutely not affected by this, on the contrary. (my ears test fine up to 18KHz)

Following the feedback from my experienced customers test listeners who validated my impressions, it became clear to me that anyone who owns these APM-33W has very much to gain from replacing the crossover filters with the Sound Oddity version. A new specification was born: to offer a plug & play filter at an affordable price which will retain all the qualities of the prototype filter (or even do better) and which will fit perfectly inside the enclosure.

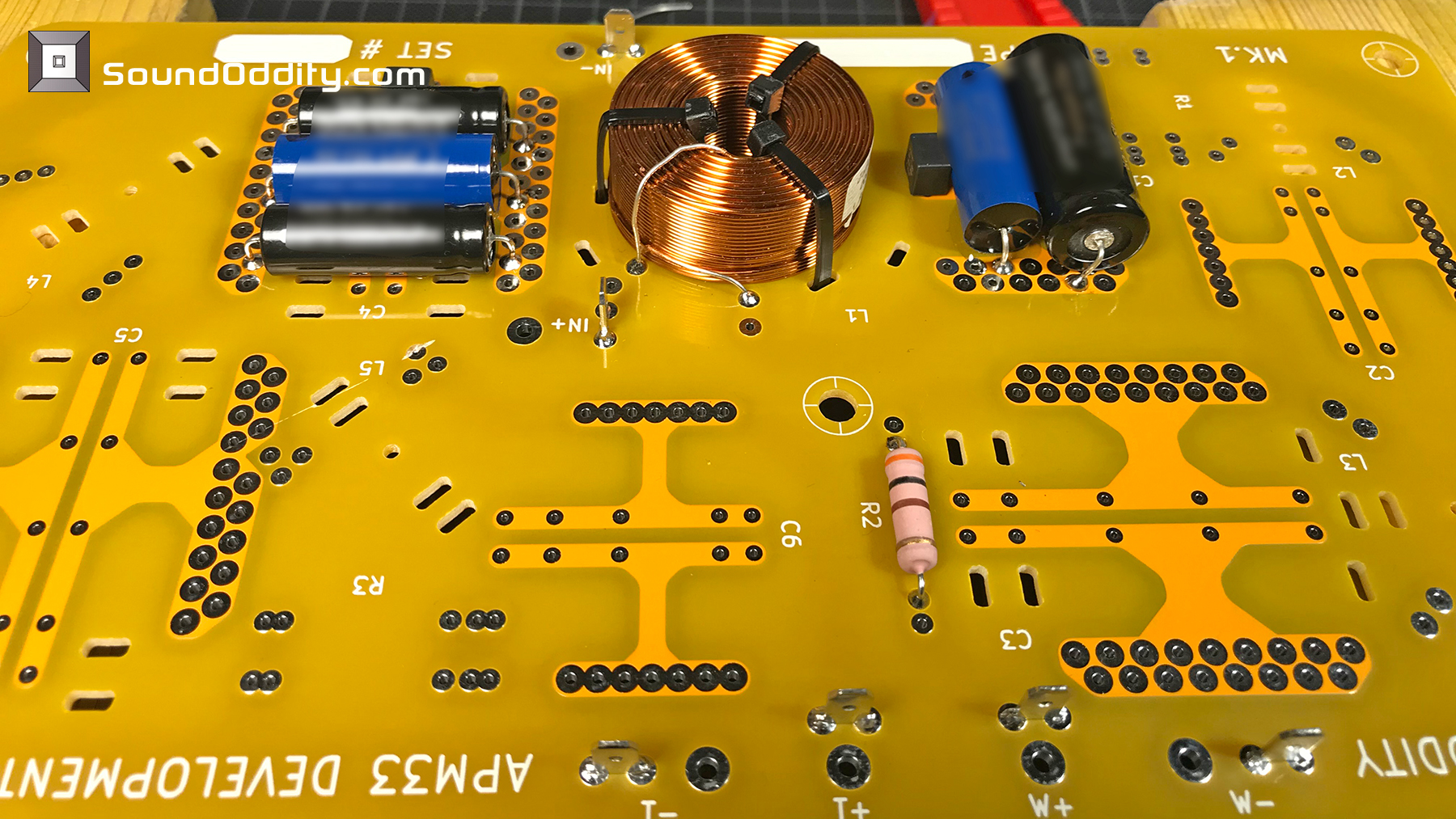

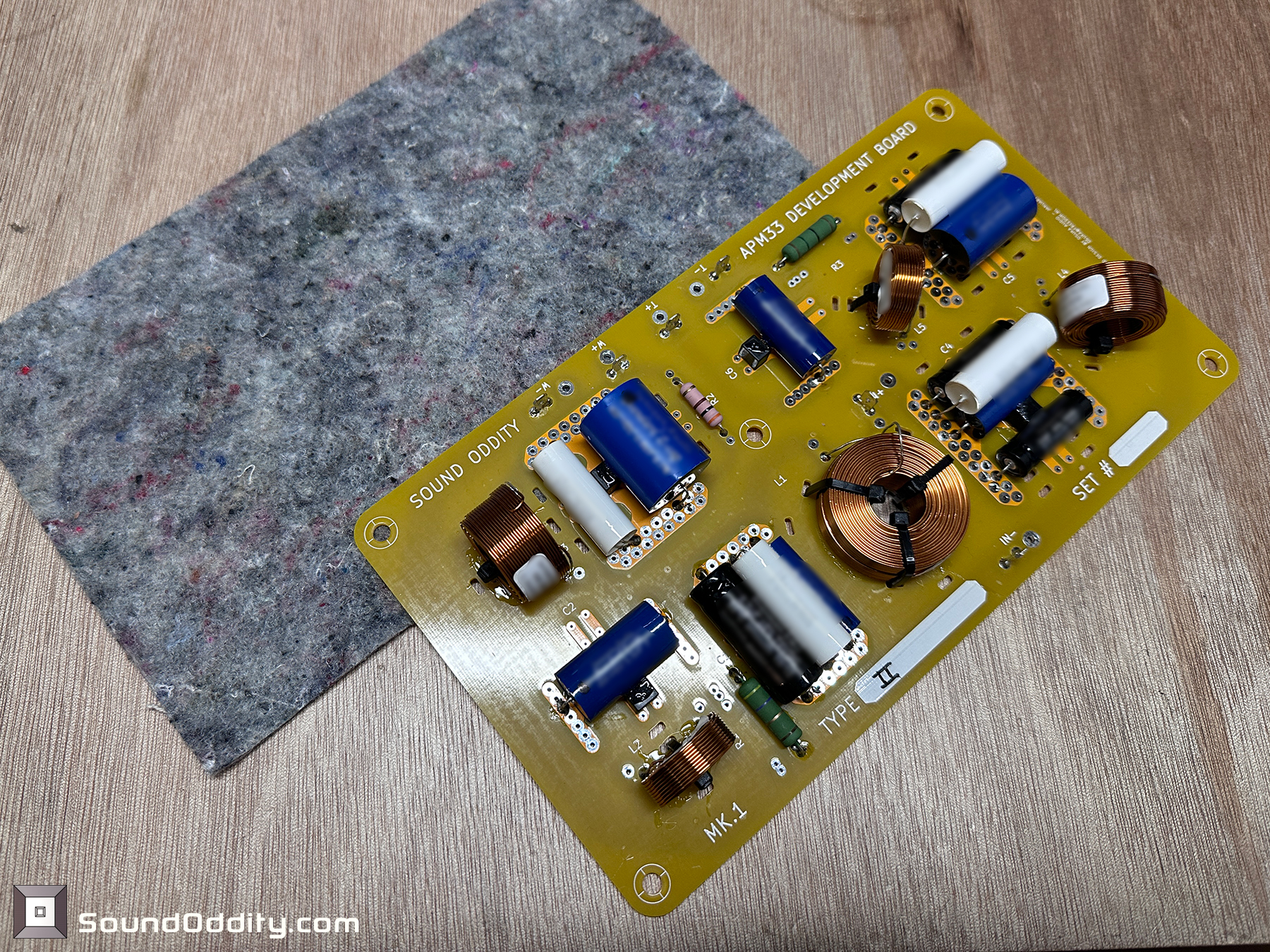

To ensure accurate reproduction and quality of the final filter design for future commercialisation, the most logical step is to build the filters on a well-studied and tested printed circuit board. However, using printed circuit boards for speaker filter design requires specific knowledge and experience in order to avoid cross currents, inadequate return current flows, cross talk, and magnetic fields of coils influencing each other.

Printed circuit boards in speakers are usually very poorly done because they must be as-compact-as-possible for commercial reasons, and thus components being positioned purely functionally against each other, avoiding segregated current flows, imposing magnetic fields across components, with tweeter and woofer related currents crossing each other. All that impacts the sonic performance of any filter very much, besides the selection of actual components. As such, printed circuit boards have a bad image in the speaker community, and who can blame them considering the above summary of problems.

However, printed circuit boards can provide a superior performance in case the component layout and track routing is done properly, as well as an accurate reproduction for commercialization compared to point-to-point soldering of loose components on a support.

Of course this does result in large boards with the woofer and tweeter sections being properly segregated, but we got plenty of space inside the APM-33.

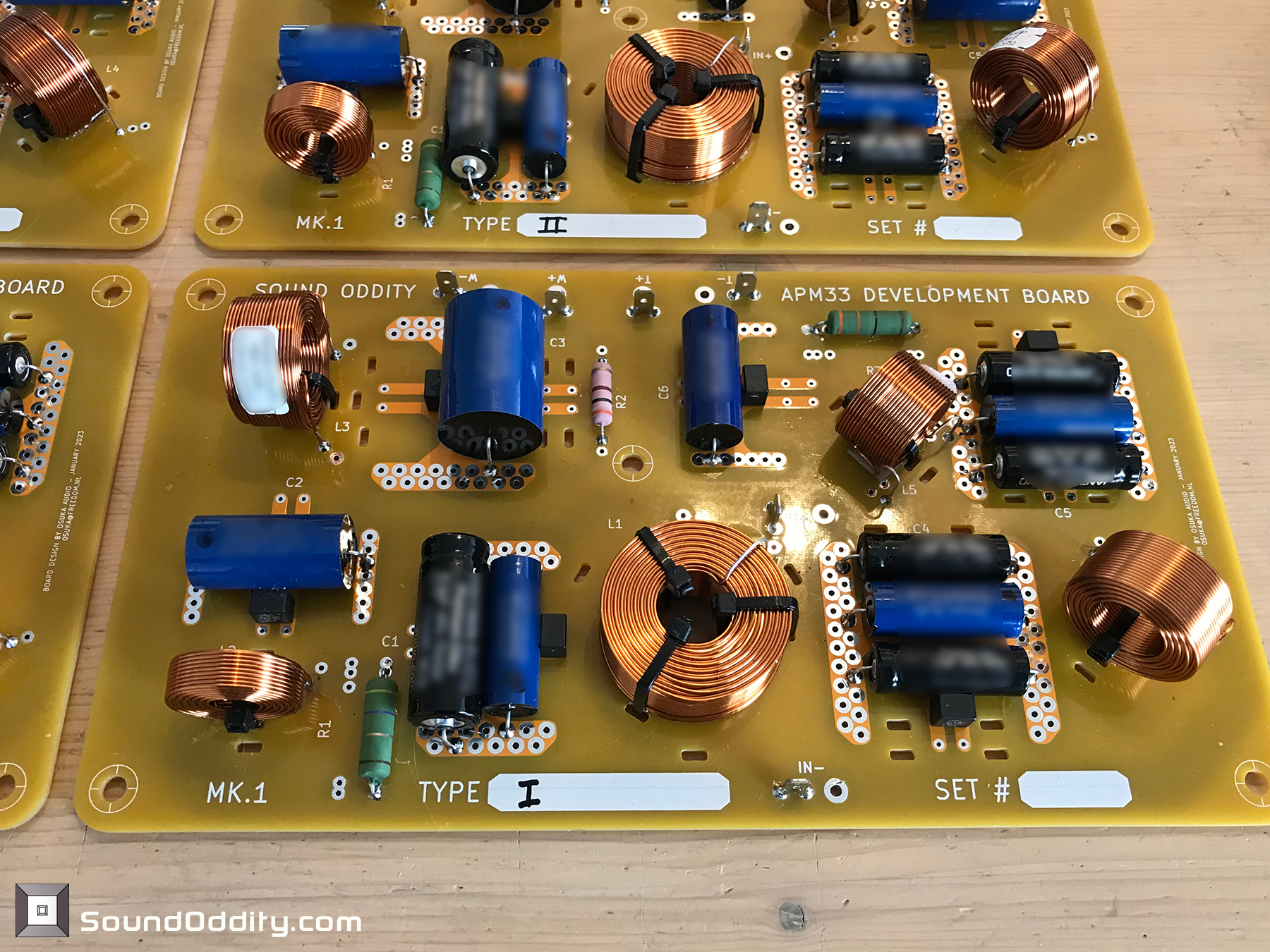

This is were my friend Oscar from Osuka Audio in The Netherlands came in the game to help me and to participate in this very cool project. Following my filtering diagram and values, he did the full development of the printed circuit board. This is a huge work of defining the correct layout and arrangement of components. Digging into each component specifications, he selected the parts for optimum quality/cost balance.

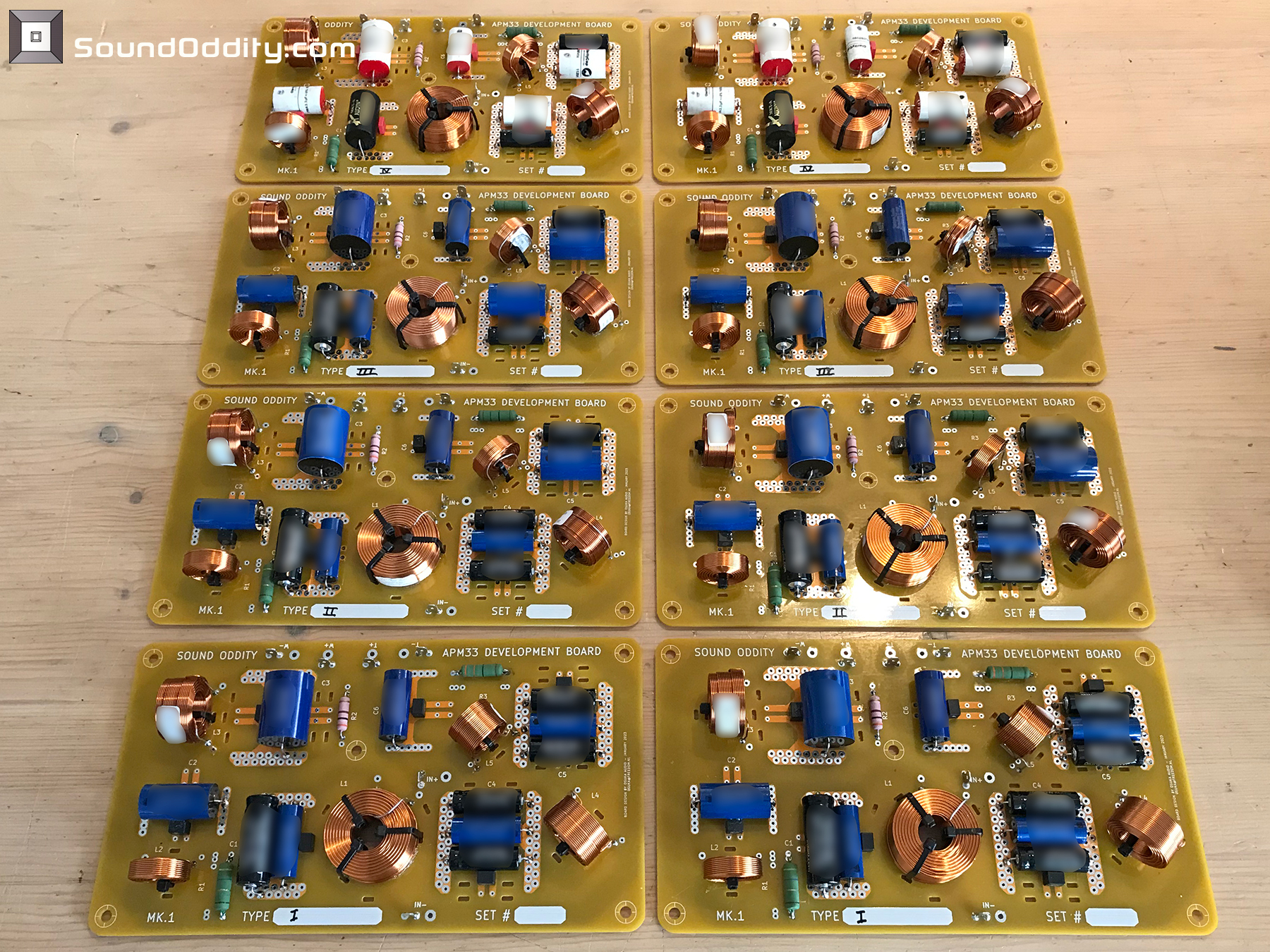

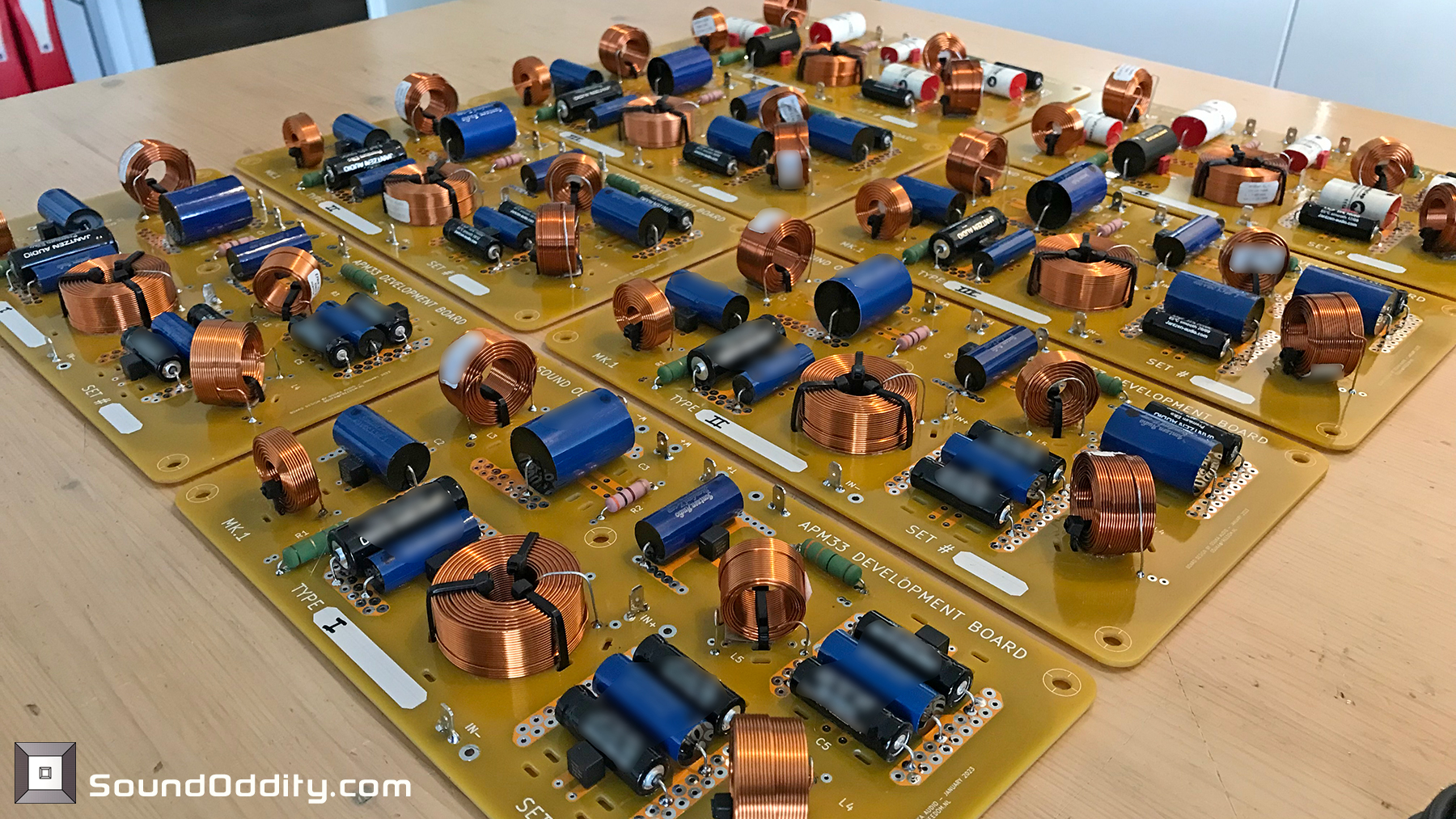

The photos below of the pre-production development boards show a matrix of soldering points around components, which allowed us to add or change components during the testing phase for optimum fine tuning and component selection.

Blending of various capacitor types and in what ratio turned out to be a worthwhile experiment. Exact matching of parts, ensuring that the filters of both speakers are within 0.5% tolerance from each other, is also key. Note that all the capacitors were tested and properly oriented.

We learned that there is much more value in proper/without industrial compromises filter arrangement/construction with proper filter design that fully compensates a driver for its shortcomings, providing an optimum crossover and balancing sound levels, than just upgrading stock filters with expensive capacitors and coils. The are high chances that replacing stock old capacitors and coils with high-end new technologies will improve the sound of your speakers but only to the point of the original crossovers limitations.

As moving from prototype to production version is not always the easiest with component selection and sourcing, 4 types of pre-production filters, with the same topology but slightly different component values and using components from different manufacturers, have been pre-selected. The numerous comparative listenings made it possible to retain the best sounding filter for mass production.

This filter, far from being esoteric, is the culmination of know-how in its layout, the arrangement of components and in the selection of components through a thorough understanding of their operation and in compliance with their specifications. It is extremely optimized to bring out the best with quality components without strongly increasing the price with the use of very high-end components. On consultation-basis only, a filter using the higher high-end components on the market can be offered to you, point to point made on a wood panel.

Here are the final characteristics obtained for the pre-production filter:

- On axis response curve within +/-1.3dB against +/-2.5dB original

- No storage of energy on the entire response against resonance at around 2.6KHz original

- Distortion more than 50dB under the on-axis response curve against about 35dB original

- Crossover frequency at around 1.8KHz against 2.6KHz original

- The response extends up to 16KHz at -3dB.

- Impedance at a minimum of 6ohm

The response which is still within +/-1.3dB may look less good than the response from the prototype filter but overall, considering the horizontal and vertical off axis dispersion, it is more balanced. In fact this pre-production filter offers even better sound reproduction than the prototype with a level of distortion even more 5dB less compared to the prototype. It comes probably from the drastic selection, matching and arrangement of components and from the fact that it is using only air core coils. Not to mention that all the capacitors are tested and oriented consequently. It does everything better than the prototype and provides the most detailed and realistic sound I ever heard and I just come back from a listening session with some Revel F328BE coupled to Mark Levinson electronics…

Here some before and after:

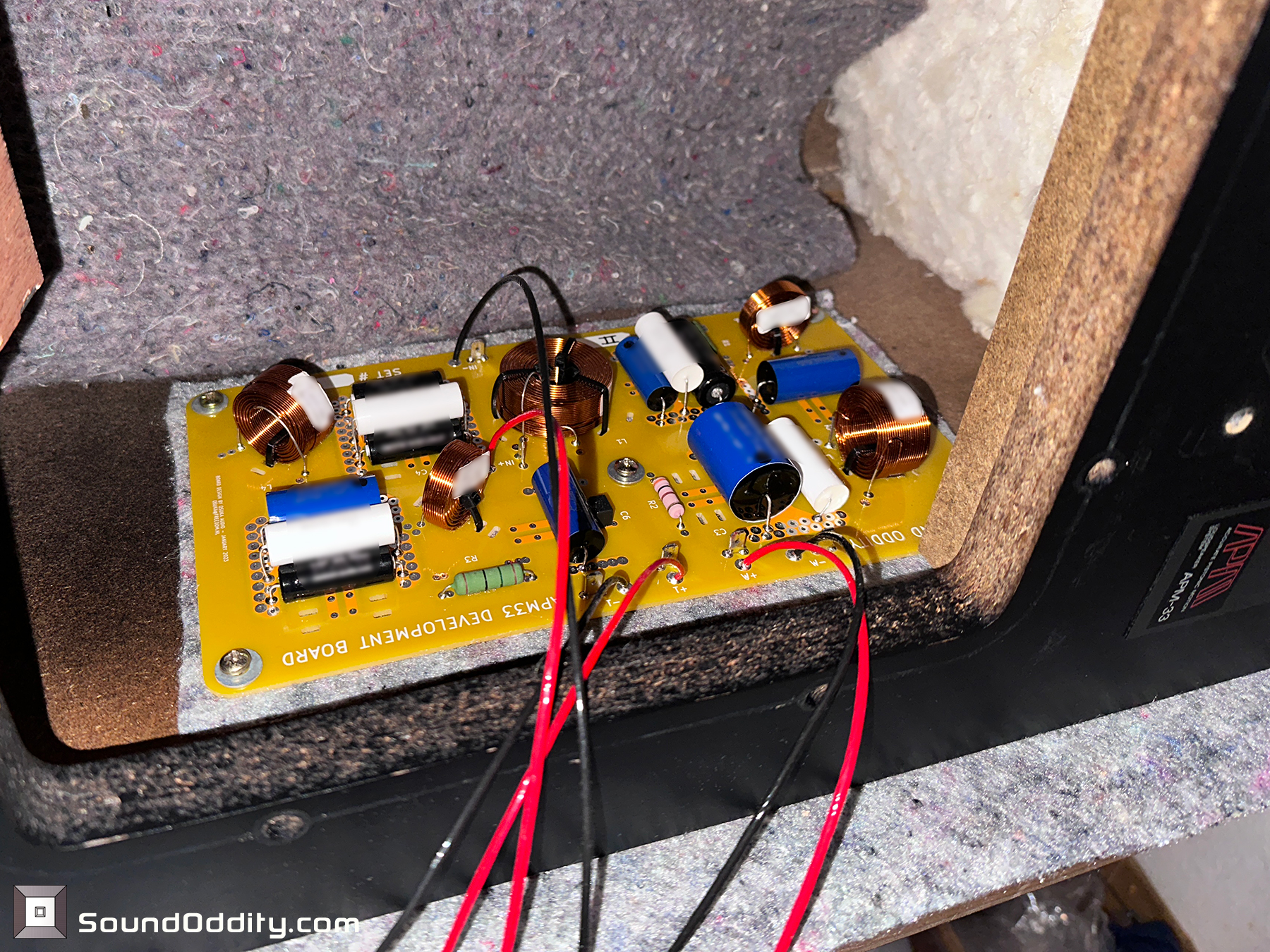

Here a few photos of the installation of the filters inside of the boxes.

The felt pad and high quality teflon insulated OFC copper wires will be offered for sale as an option. An extra back plate with gold platted copper binding posts accepting banana plugs can also be offered for sale as an option.

As these APM-33W became my reference speakers, I decided to build some custom stands for them. These were quickly made with scraps as prototype stands: